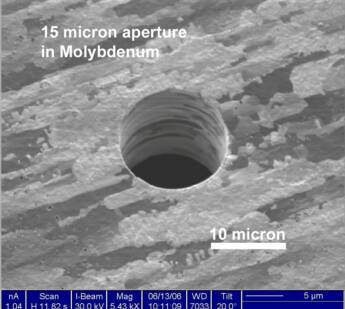

For the production of apertures below about 10 microns in diameter, focused ion beam processing is most effective in creating clean, round penetrations.

A great variety of thinned metals have been penetrated at Norsam using FIB, including Molybdenum, Titanium, Tungsten, Platinum, Gold, Copper and Chromium.

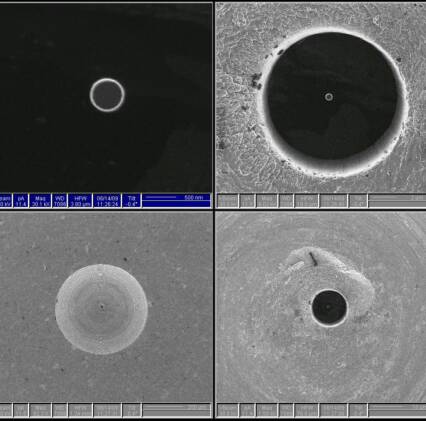

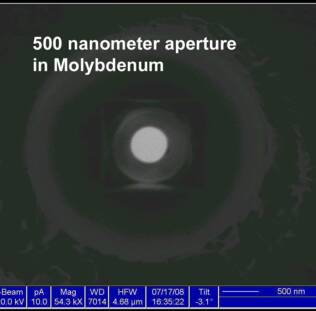

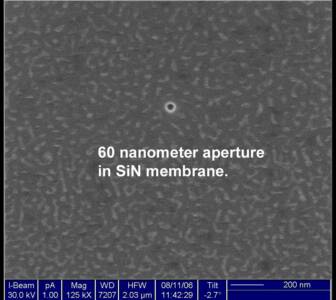

Some very tiny penetrations are feasible using FIB processing of highly thinned metallic foils and ceramic membranes.

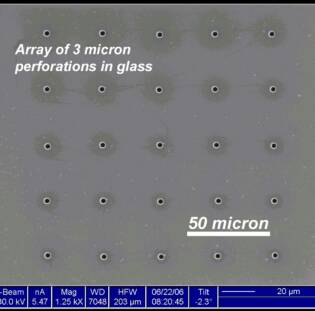

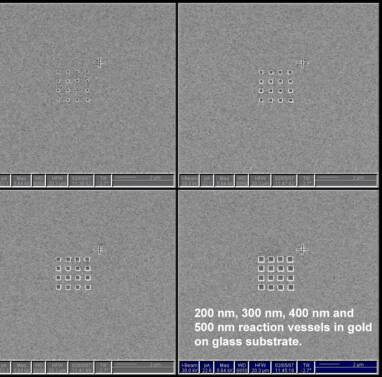

Arrays of recessed features may be prepared in glass, quartz, sapphire and other nonconductive materials using FIB, so long as a conductive layer of gold or carbon is provided to ground the charged particle beam.

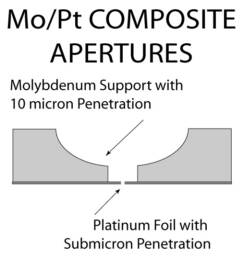

Handling a submicron feature-- or even finding it-- may present difficulties. For the tiniest of apertures, Norsam Technologies has solved these problems by developing Molybdenum-Platinum Foil Composite apertures. The sturdy Mo support for the Pt foil contains a visible counterbore, locating the penetration site like a bullseye.