the HD-ROSETTA Disc

Los Alamos Labs tested the

HD-ROSETTA Disc and issued the following report:

Los Alamos National Laboratory, an affirmative action/equal opportunity

employer, is operated by the University of California for the U.S.

Department of Energy under contract W-7405-ENG-36. By acceptance of this

article, the publisher recognizes that the U.S. Government retains a

nonexclusive, royalty-free license to publish or reproduce the published

form of this contribution, or to allow others to do so, for U.S.

Government purposes. The Los Alamos National Laboratory requests that the

publisher identify this article as work performed under the auspices of

the U.S. Department of Energy. Los Alamos National Laboratory strongly

supports academic freedom and a researcherís right to publish; therefore,

the Laboratory as an institution does not endorse the viewpoint of a

publication or guarantee its technical correctness. A Survey of the Environmental Degradation Resistance of

the HD-Rosetta Data Storage Disc LA-UR-99-0441 January 31, 1999

Please note: Because of limitation involved with

preparing images for the Web, the images in this document are not as sharp

as in the original.

Jennifer A. Lillard

Materials Science and Technology Division

Los Alamos National Laboratory

Los Alamos, NM 87545

Abstract

The HD-Rosetta data storage disc exhibited good degradation resistance in elevated temperature air and a low corrosion rate in several aqueous environments. The disc examined, which contained thousands of pages of analog data in the form of microscopic images and text, was composed of a thin layer of nickel on a silicon substrate. The text was formed from a master during deposition of the nickel layer. Elevated temperature air was used to simulate fire conditions, and aqueous corrosion testing simulated several scenarios that could occur with a loss of the controlled storage environment. For temperatures up to 300 oC (570 oF) and times up to 65 h in laboratory air, the text remained readable. Exposures to saltwater, tap water, and a simulated marine air environment for 15 weeks did not affect readability of the text. The corrosion rate was measured as a function of time for seven days and was approximately 1 mm per year, which suggested that the disc could survive a long time in the saltwater if the environmental conditions remained the same. However, these results cannot be extrapolated to very long times because chemical changes in the environment that may take place with time were not taken into account.

Background

The objective of this work is to examine the environmental degradation resistance of HD-Rosetta* discs, which are intended to provide long-term analog (image) data storage. Each disc is 2.2 inches in diameter and contains approximately 9000 pages of text or images. The discs are made by covering a silicon wafer substrate with a thin (~400 mm) layer of nickel. The nickel layer, which contains the text, is formed from a master disc using an electroforming process. The height of the lines that make up the letters and images on the master disc is very small, less than about 100 nm.

The results presented below simulate two possible scenarios: (1) fire conditions and (2) corrosive conditions that could arise in the case of a flood or if control of the storage atmosphere was lost. Heat treatment in air and aqueous exposure tests were used to simulate the two scenarios. Electrochemical testing was performed to measure the corrosion rate of the disc in saltwater.

Experimental

Test Disc

The disc provided was a "mother" from Sanyo/Verbatim (#4). "Mother" indicates that the lines of text and images are recessed into the nickel layer. The disc was shiny and silver in color. Pages of text were visible to the naked eye as whitish rectangles on the disc. The text sequence was the first six pages of the Bible followed by a test pattern. This sequence was repeated over approximately half of the disk; the other half was blank. Experiments were conducted on portions of the disc that contained pages of text.

Sample Preparation

Samples were cut from the test disc using a slow speed saw that was cooled with a water-soluble cutting fluid. The disc was mechanically clamped at the edges, which did not contain text, and a diamond wafering blade was used to cut rectangular samples that were approximately 3 mm by 4 mm. Each sample was ultrasonically cleaned in three solutions: (1) mild soap solution for 10 minutes, (2) distilled water for 10 minutes, and (3) ethanol for 5 minutes. The samples were removed from solution using tweezers and dried with clean, compressed gas. Samples were then stored in airtight containers and examined under an optical microscope for cleanliness before testing.

Metric

Degradation was measured using several metrics. The first was overall appearance of the disc (e.g., visible oxidation of surface). Second, the text was examined optically at 400x magnification for microscopic damage and 1000x magnification for readability. Finally, scanning electron microscope (SEM) images were taken at higher magnifications to look for small changes in the text and test pattern.

Corrosion Resistance

Samples were exposed to saltwater, tap water, and a simulated marine air environment to qualitatively examine the corrosion resistance. The saltwater was a solution of 3.5 % by weight sodium chloride made with distilled water, and the tap water was drawn from a tap at Los Alamos National Laboratory. For each environment, approximately 50 ml of solution was poured into a clean plastic 250-ml jar. A test sample was placed at the bottom of the jar, and the jar was sealed. Marine air was simulated by pouring 50 ml of the saltwater into a jar, placing a smaller plastic container at the bottom of the jar, and setting a test sample on top of the smaller container so that it was exposed to the air but not the solution. The jar was then tightly sealed. A total of nine jars were prepared, three for each environment. The jars were left in the laboratory and samples were examined periodically.

The polarization resistance method was used to calculate the corrosion rate of a disc sample exposed to salt water. This method relies on the fact that, at a given applied current, the degree of polarization is greater for a lower corrosion rate, and it is widely accepted due to the correlation between the theory and experimental observations . The polarization resistance was measured experimentally using the linear polarization technique, which is non-destructive. A detailed description of the experimental technique and derivation of the equations are given in Jones . Errors due to uncertainty in Tafel constants and nonlinearity of polarization curves were not accounted for because these errors were not expected significantly change the result . The tests were performed on a 0.3 cm2 sample in the 3.5 % sodium chloride solution under quiescent exposure to air.

High-Temperature Oxidation Resistance

An air furnace was used to simulate high-temperature conditions that might be encountered in a fire situation. Samples were heated to temperatures ranging from 100 oC (210 oF) to 550 oC (1000 oF) for times ranging from 24 h to 65 h.

Results

High-Temperature Oxidation

At temperatures of 100 oC (210 oF) and 300 oC (570 oF) there was little or no degradation of the disc for exposures up to the longest test time of 65 h. The sample surfaces remained shiny and in some cases had a gold tint. In all cases, the rectangles representing the pages of text were clearly visible.

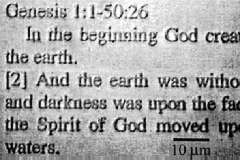

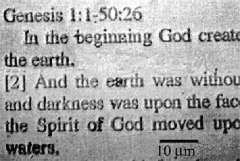

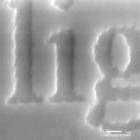

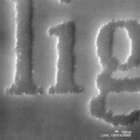

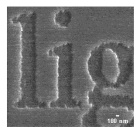

Optical microscopy at 1000x magnification (Figure 1) showed little difference between an as-received sample and one exposed to air at 300 oC (570 oF) for 24 h. There were small changes in the coloration of the surface and some of the letters in the heat-treated sample, but these changes did not affect the readability of any of the text. This observation was confirmed by SEM examination, which revealed that the text and test patterns were practically identical for the two test conditions. Figure 2 shows an SEM image of the text at 20,000x magnification. At this magnification the sample exposed to 300 oC (570 oF) air for 24 h shows small spots on the letters, which may or may not be due to the heat treatment. However, the spots do not affect the readability and the edges of the letters do not appear to be rougher than the as-received sample. Pictures of the smallest test pattern are shown at 4500x magnification in Figure 3. There is no perceptible difference in the pattern for the as-received and heat-treated samples. The bulk surface of the heat-treated sample looks slightly different than that of the as-received sample, and it appears that some of the grain structure is visible.

(a)

(b)

Figure 1. Optical micrographs (1000x magnification) comparing the readability of text for (a) an as-received sample and (b) one exposed to air at 300 oC (570 oF) for 24 hours.

(a)

(b)

Figure 2. Scanning electron micrographs show that there is little difference in the quality of the text at 20,000x magnification for (a) an as-received sample and (b) a sample exposed to air at 300 oC (570 oF) for 24 hours.

(a)

Figure 3. Scanning electron micrographs showing that there is no apparent difference in the quality of the smallest test pattern at 4500x magnification for (a) an as-received sample and (b) one exposed to air at 300 oC (570 oF) for 24 hours.

A sample exposed at 300 oC (570 oF) for 65 h showed significant discoloration on some areas of the sample surface. At 20,000x magnification, very small patches (about 200 nm diameter) were observed at the edges of a small percentage of the letters. The patches were likely an oxide that resulted from the reaction of nickel with the oxygen in air at 300 oC (570 oF). All of the text was still readable as shown in Figure 4.

(a)

Figure 4. Scanning electron micrographs of a sample exposed to air at 300 oC (570 oF) for 65 hours show that (a) in some areas the text appears pristine and (b) in areas with discoloration, the discoloration of the sample does not affect the readability of the text.

Readily observable degradation occurred when samples were exposed to air at 450 oC (840 oF) and 550 oC (1020 oF) for 24 h. During the 450 oC (840 oF) exposure an oxide formed on a few areas of the sample and destroyed the text in those areas. In regions not covered by the oxide, the text and test patterns were easily readable (Figure 5). After the 550 oC (1020 oF) exposure, an oxide layer covered most of the surface. Individual pages of text were visible to the naked eye, but the letters were unreadable under microscopic examination. In an inert, oxygen-free atmosphere, oxidation of nickel would be suppressed and degradation would be dominated by diffusion of nickel atoms to produce grain growth and smearing of the letters. Therefore, it would be expected that higher temperatures and longer times could be tolerated in an inert environment.

Figure 5. Scanning electron micrograph of a sample exposed to air at 450 oC (840 oF) for 24 hours shows that the formation of an oxide layer renders parts of the text unreadable.

Corrosion

Samples were removed from the saltwater, tap water, and simulated marine air environments after 1, 2, and 15 weeks of exposure and then examined. Optical and scanning electron microscopy showed that none of the samples had corrosion pits and that the only discernable change in the quality of the text was a small amount of roughening of the bottom surface of the letters. Figure 6 shows SEM micrographs taken after 15 weeks of exposure for the marine air environment. The condition shown in Figure 6 is representative of the condition of the samples exposed to saltwater and tap water.

Figure 6. SEM micrographs of the disc sample exposed to the marine air environment showing that little degradation was observed for a 15-week exposure. The micrographs shown are representative of the condition of the samples exposed to saltwater and tap water.

The corrosion rate as a function of time, which was determined using the linear polarization resistance (LPR) method, is shown in Figure 7. The corrosion rate represents the thickness of material that is corroded away from the surface of the sample per year. Overall, the corrosion rate was low. During the first few days, the corrosion rate decreased and then stabilized to a value of less than 1 mm per year (mmPY). Near the end of the test, at approximately 7 days, the corrosion rate increased slightly, which may indicate that the long-term corrosion rate is somewhat higher. The LPR results, as well as microscopic observations from the exposure tests, suggest that corrosion of the bulk surface and the text occur at similar rates. If the corrosion rate were 1 mmPY on the bulk surface but close to zero at the text, the text would become unreadable within several days because the depth of the text is very small. Furthermore, if the text corroded at a much higher rate than the bulk surface, the edges of the text would likely become distorted. Assuming that the 7-day test represents equilibrium conditions with a corrosion rate of 1 mmPY in salt water and assuming the thickness of the nickel layer is uniformly 400 mm, the text should remain readable for 400 years. However, the assumption that the 7-day test represents equilibrium is overly optimistic. With time, the solution chemistry (e.g., pH) will likely change, and localized corrosion processes, such as crevice corrosion and pitting, may occur. Also, condensation and evaporation in a moist air environment will increase the corrosion rate.

Summary

The HD-Rosetta, an analog, data storage disc, was resistant to degradation at moderate temperatures in stagnant air. At times up to 65 h, little or no degradation occurred for temperatures up to 300 oC (570 oF). At 450 oC (840 oF) and higher oxidation of the nickel surface occurred, which rendered parts of the text unreadable. If the discs were stored in an inert gas atmosphere, it is expected that they would resist degradation at temperatures above 300 oC (570 oF).

Results of exposure and electrochemical tests indicate that the HD-Rosetta disc had a high resistance to corrosion in saltwater, tap water, and marine air. After 15 weeks of exposure no pitting was observed for any of the environments, and the text appeared almost pristine. The corrosion rate n 3.5% sodium chloride, as calculated by linear polarization resistance during a 7-day test, was on the order of 1 mm per year. Extrapolation of the corrosion results to very long times is not prudent because chemistry changes in the environment may cause localized corrosion.

References 1. Stern, M. and A.L.

Geary, J. Electrochem. Soc., 1957. 104: p. 56.

2. Stern, M.,

Corrosion, 1958. 14: p. 440t.

3. Wagner, C.W. and W. Traud, Z.

Elektrochem., 1938. 44: p. 391.

4. Simmons, E.J., Corrosion, 1955. 11:

p. 255t.

5. Skold, R.V. and T.E. Larsen, Corrosion, 1957. 13: p. 139t.

6. Bonhoeffer, K.F. and W. Jena, Z. Elektrochem., 1951. 55: p. 151.

7. Jones, D.A., in Principles and Prevention of Corrosion. 1996, Simon

& Schuster: Upper Sadle River, NJ. pp. 143-165.

8. Stern, M. and

E.D. Weisert, Proc. ASTM, 1959. 32: p. 1280.