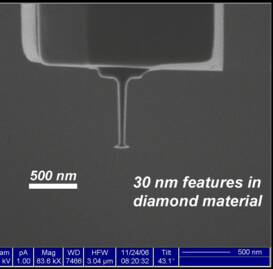

Diamond material retains a great deal of integrity at the microscale and can support resilient features less than 100 nm in size. This makes diamond a preferred material from which to fabricate microscopic styli, indenters, and other tools.

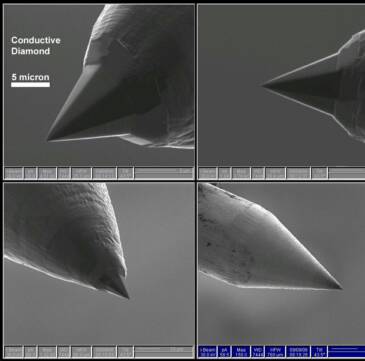

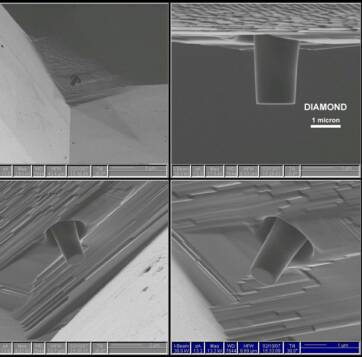

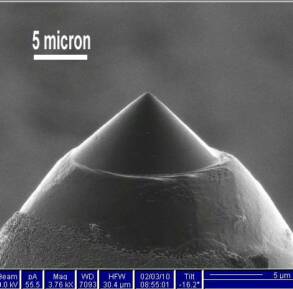

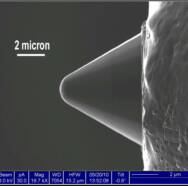

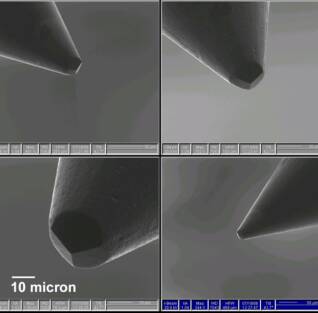

A diamond stylus may be mechanically polished only to an apex of at best one or two microns radius of curvature. Fortunately, focused ion beam processing can pick up from there to create radii down to 20 nanometers, putting a very fine point on the stylus.

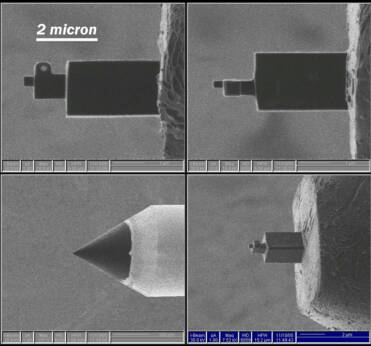

Using a variety of techniques, a surprising array of projecting features can be created in diamond using FIB technology. In every case, the material must be selectively removed to reveal the feature. Single-crystal diamond with few impurities or inclusions is best for FIB processing.

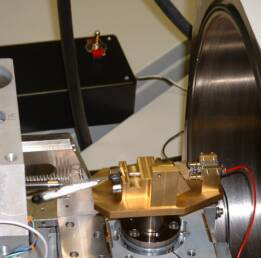

Norsam Technologies, Inc. has developed the capability to fabricate fully-turned features, such as conical shapes and ball indenters, using a lathe-style apparatus.

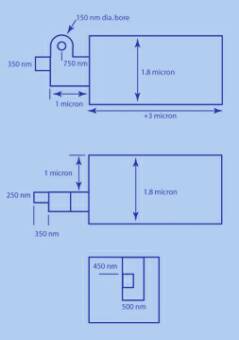

Nanoindenters of several varieties can be produced by Norsam Technologies using FIB processing and specialized fixturing.

Unique shapes and unusual geometries in diamond are a specialty at Norsam Technologies. We can help you to literally get a handle on microscopic tools of your own concept and design, to assist in your research or production goals. Contact us to discuss your microscopic tooling needs-- we may well be able to help you.